PLC AND SYSYTEM INTEGRATION

System integration is defined in engineering as the process of bringing together the component sub-systems into one system (an aggregation of subsystems cooperating so that the system is able to deliver the overarching functionality) and ensuring that the subsystems function together as a system.

The system integrator integrates discrete systems utilizing a variety of techniques such as computer networking, enterprise application integration, business process management or manual programming.

Some integration projects are:

- Inkjet Printer integration with PLC

- PLC integration with Lab view

- Label Printer integration with Lab view

- Vision camera integration with injection moulding machine

- Servo traversing integration with inkjet printer in Production line machines

- Vision camera integration with printing applications

- Conveyor system integration with Robot

- Vision system integration with Robot

- Robot integration with injection moulding machine

- Conveyor system integration with injection moulding machine

- SCADA integration with PLC

- SCADA integration with filling and Mixer Automation for Process monitoring

APPLICATION USES:

- Food Industries

- Pharma Industries

- Automative

- Manufacturing Sector

INKJET PRINTER INTEGRATION WITH PLC

- Inkjet printer integrated with PLC for online printing process.

- Communication required between Ink-jet printers to PLC is RS232.

- Communication can be done with printer by any available communication protocol in printer.

- Automatic print data collection from Lab VIEW through PLC so No man power requires to enter data.

APPLICATION:

- Food Industries

- Pharma Industries

- Automative

- Manufacturing Sector

PLC INTEGRATION WITH LAB VIEW

- PLC integrated with lab VIEW to perform online data monitoring and data logging in conveyor system for the products travelling in the conveyor.

- Auto monitoring and data logging so man power will be reduced.

APPLICATION:

- Food Industries

- Pharma Industries

- Automative

- Manufacturing Sector

LABEL PRINTER INTEGRATION WITH LAB VIEW

- Label printer integrated with lab VIEW to perform online data label printing and data logging in production and packaging lines.

- Online printing will happen automatically so save the excess printing time and labor.

APPLICATION:

- Food Industries

- Pharma Industries

- Automative

- Manufacturing Sector

VISION CAMERA INTEGRATION WITH INJECTION MOULDING MACHINE

- Vision camera integrated with injection moulding machine to perform online inspection of production.

- Avoid major accidents.

- Protect mould from Runner and component catching issues.

APPLICATION:

SERVO TRAVERSING INTEGRATION WITH INKJET PRINTER IN PRODUCTION LINE MACHINES

- Servo traversing integrated with inkjet printer in production line to perform online printing at the time of production itself.

- It reduces individual printing time, Labor& printing cost.

- Suitable for all kinds of printers.

APPLICATION:

- Food Industries

- Pharma Industries

- Automative

- Manufacturing Sector

VISION CAMERA INTEGRATION WITH PRINTING APPLICATIONS

- Vision camera integrated with printing applications to perform online inspection of printing auto correction.

- Inspection can be done online so it reduces inspection time.

- Auto correction can be done automatically so it reduces rejection percentage.

- Both inspection and correction are auto process so it reduces man power and process time.

APPLICATION:

- Food Industries

- Pharma Industries

- Automative

- Manufacturing Sector

CONVEYOR SYSTEM INTEGRATION WITH ROBOT

- Conveyor system integrated with robot to perform collect material from robot and feed material to robot based on robot feedback signals.

- Operates based on feedback signals so avoids accidents.

- Reduces power consumption.

- Reduces man power.

APPLICATION:

- Food Industries

- Pharma Industries

- Automative

- Manufacturing Sector

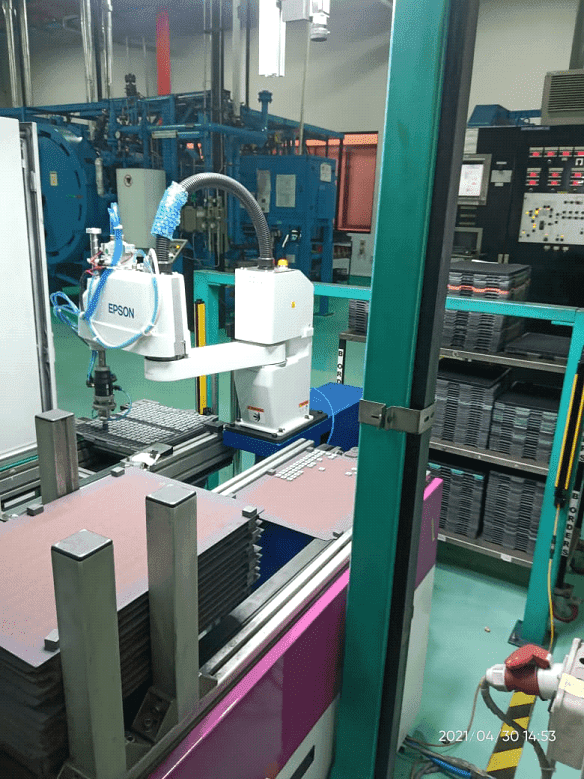

VISION SYSTEM INTEGRATION WITH ROBOT

- Vision camera integrated with robot to perform pick and place operations effectively.

- Increase the performance and reduce the damages.

- Wrong picking and wrong placing can be avoided.

- Avoids accidents.

APPLICATION:

- Food Industries

- Pharma Industries

- Automative

- Manufacturing Sector

ROBOT INTEGRATION WITH INJECTION MOULDING MACHINE

- Robot integrated with Injection moulding machine to collect material from Injection moulding machine based on Injection moulding machine feedback signals.

- Operates based on feedback signals so avoids accidents.

- Reduces power consumption.

- Reduce man power.

APPLICATION:

CONVEYOR SYSTEM INTEGRATION WITH INJECTION MOULDING MACHINE

- Conveyor system integrated with Injection moulding machine to collect material from Injection moulding machine based on Injection moulding machine feedback signals.

- Operates based on feedback signals so avoids accidents.

- Reduces power consumption.

- Reduce man power.

APPLICATION:

SCADA INTEGRATION WITH PLC

- PLC integrated with SCADA to perform online data monitoring and data logging in conveyor system for the products travelling in the conveyor.

- Auto monitoring and data logging so man power will be reduced.

APPLICATION:

- Food Industries

- Pharma Industries

- Automative

- Manufacturing Sector

SCADA INTEGRATION WITH FILLING AND MIXER AUTOMATION FOR PROCESS MONITORING

- SCADA integrated with filling and mixer automation to perform online data monitoring and data logging in process automation.

- Auto monitoring and data logging so man power will be reduced.

- Avoids accidents.

APPLICATION:

- Food Industries

- Pharma Industries

- Automative

- Manufacturing Sector